What is a Type of Hand Operated Winching Device?

What is a type of hand operated winching device? Manual, geared, ratchet, and lever winches suit different loads, safety needs, and environments.

Welcome to the Powerful Machinery resource center. Here, our experts share deep insights into the science of lifting, rigging, and mooring. Explore technical guides on everything from wire ropes to anchor chains and hardware, helping you engineer safer, more reliable solutions.

What is a type of hand operated winching device? Manual, geared, ratchet, and lever winches suit different loads, safety needs, and environments.

Follow this guide on how to use a manual winch safely, including setup, operation, and essential safety tips to prevent injuries and equipment damage.

Compare the top 8 manual winch manufacturers for 2026, focusing on quality, innovation, certifications, and unique features for industrial and commercial use.

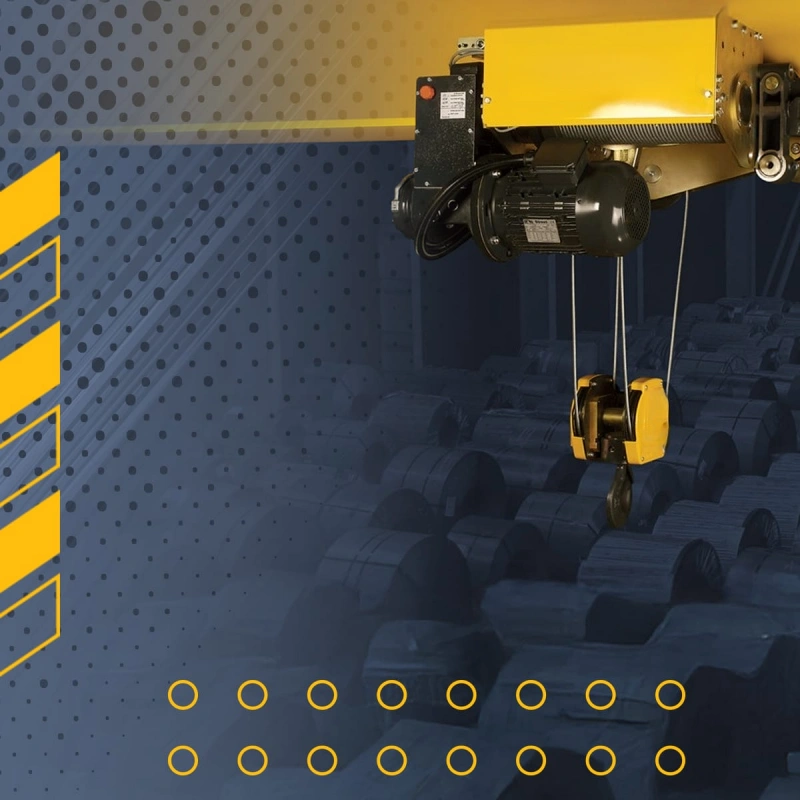

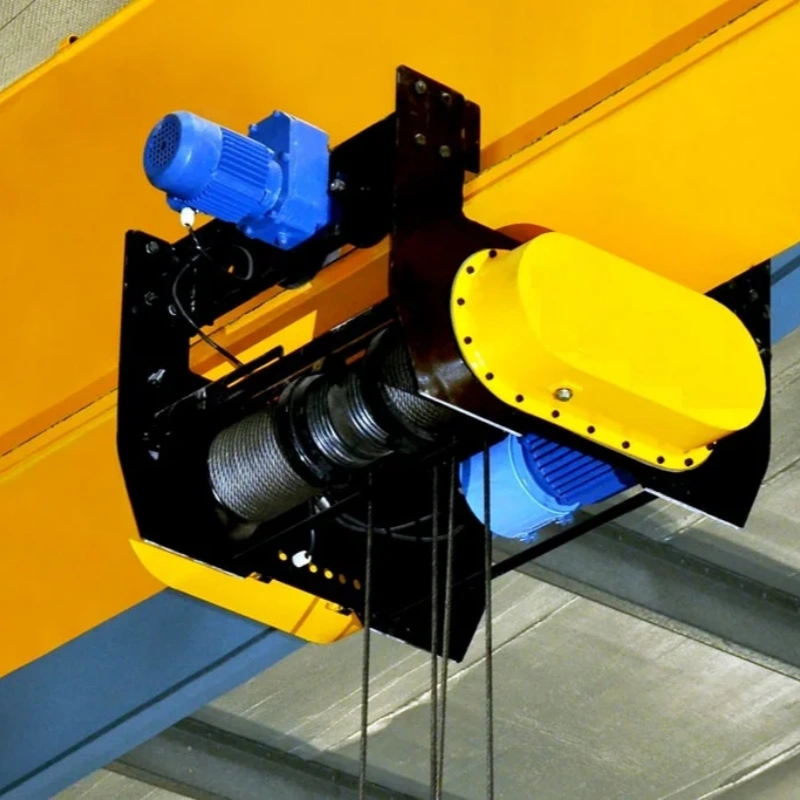

Select electric hoist parts that match your load, environment, and safety needs for reliable, efficient industrial lifting and reduced downtime.

Top electric hoist suppliers for 2026: compare certifications, reliability, and innovation to find the best fit for your business needs.

Electric Hoist Market analysis: size, growth outlook, tech trends, segmentation, drivers, challenges, and automation impact across major industries by 2026.

Electric hoist troubleshooting and maintenance guide covering common failures, repair steps, preventive care, and safety tips to extend equipment lifespan.

Electric hoist installation guide: choose equipment, mount safely, follow codes, and maintain your hoist for reliable garage lifting operations.

Top electric wire rope hoist suppliers for 2026 ranked by quality, certifications, and after-sales support for industrial lifting needs.

Chain blocks use gears and chains to lift heavy loads safely. Compare types, mechanisms, industry uses, and get essential safety and maintenance tips.

A trolley hoist combines vertical lifting and horizontal movement, letting you move heavy loads safely and efficiently along beams in industrial settings.

Manual hoist repair made safe: follow step-by-step inspection, part replacement, and testing tips to protect yourself and ensure reliable lifting.

After downloading the product catalogue, our dedicated technical experts will provide you with one-on-one service.